Extraction system for the Sainsmart CNC

The Story

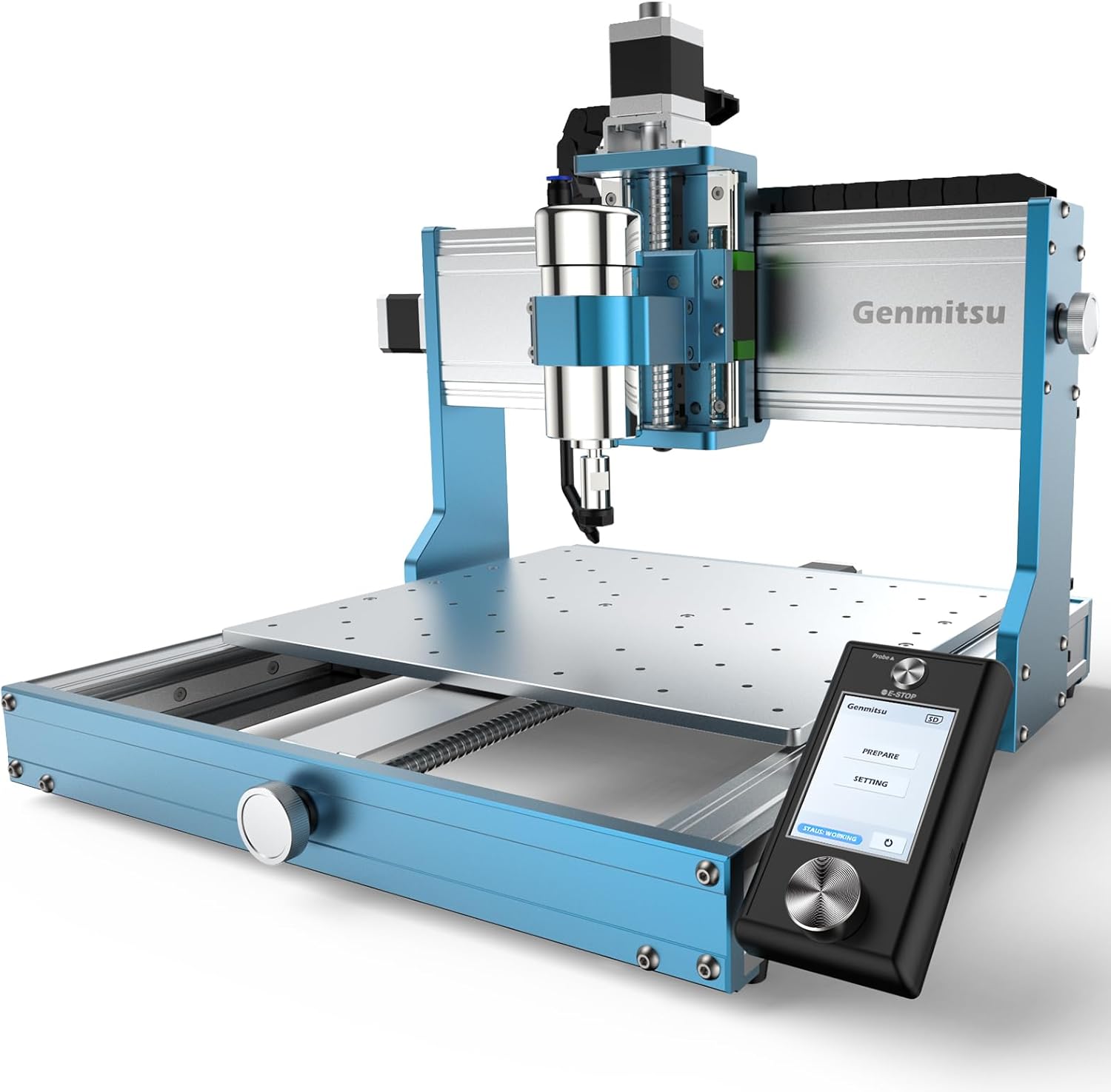

I recently bought the Genmitsu Sainsmart 3030-PROVer MAX so I can finally CNC mill small projects at home. Since I also work with wood, which produces a lot of shavings, and PCBs, which release hazardous substances, and I want to use the milling machine in my apartment, I need a reliable dust extraction system.

Why Make It Yourself

Since the CNC manufacturer already offers suitable accessories, the question arises: why develop one yourself instead of simply buying one? Well, that may be true to some extent, but what I make myself fulfills exactly the function I need it to. The manufacturer's dust extraction system has long brushes, which adapt nicely to contours, but their length isn't adjustable, which sometimes leads to poor suction performance and also to increased wear.

Additionally, the manufacturer attaches it to the outer diameter of the motor, which insulates it, meaning it will heat up more, and secondly, the motor can no longer be lowered completely when a longer cutter or a larger workpiece is clamped in place. Yes, there are two different lengths and it's held in place magnetically, which I unfortunately can't highlight as a positive feature, since the cover has to be removed downwards. This means I have to be next to, or far above, the workpiece to change, remove, or attach the cover, which ultimately means I have to pause the work.

Unfortunately, I'm also not a fan of making something like this magnetic, because with strong vibrations or if the long bristles get caught, the cover could come loose and cause serious damage to the small milling cutters.

The dust shue cover is only attached with a set screw, and I'm not sure how reliably that will hold with a rigid vacuum hose.

Additionally, I would have to print an adapter connection for the vacuum cleaner anyway, which can only be secured by clamping, which is particularly questionable with transparent plastic, because in my experience, transparent plastic, while rigid, is also very brittle and breaks very easily. No, that wouldn't work.

The Basic Concept

Initially, I considered whether I would need to use cooling in addition to dust extraction if I wanted to mill aluminum. Since I couldn't find any information on this online, I had to come up with my own solution. Based on the advice of most CNC technicians, who strongly recommend using compressed air, especially for deep pockets, I wondered why blow the chips away when I could simply vacuum them up. The advantage of compressed air is that the nozzle can be positioned further away than with a dust extraction system. Dust extraction only works effectively if it surrounds the cutter, and the air gap between the extraction system and the workpiece needs to be significantly smaller, which becomes difficult with complex shapes. Therefore, dust extraction isn't practical for deep, large pockets. That's why every professional CNC technician uses compressed air or liquid coolant. Since the milling machine is small and mainly handles simple shapes, at least for now, and especially for fiber composite boards, which I absolutely want to mill, it works.

And then it occurred to me: all PCB plotters (milling machines used for circuit board production) have a dust extraction system to immediately remove the hazardous glass fibers.

Choosing the Vacuum Cleaner

Before designing anything for a vacuum cleaner, you have to decide which one, as this could lead to different design decisions.

Requirements for the vacuum cleaner:

- It must be at least an M-certified vacuum cleaner and ideally equipped with an H filter

- It should be a vacuum cleaner for which you can simply replace bags and Replacement filters are available that are of good quality. Ideally with antistatic properties. Ideally, the suction power should be adjustable.ar

- Ideally, automatic filter cleaning

Ultimately, I chose the Bosch GAS 35 because it's available in every good local hardware store, and I also made sure I could easily get replacement bags.

Calculating the Diameter

Now the question is, what diameter should the pipe be? The extraction shouldn't be too large, because then the suction power would be too low, and we only have limited space. It also shouldn't be too small, because then the connected vacuum cleaner would be unnecessarily strained, and the suction power would decrease again.

So I took the handpiece and measured at its thinnest point. Then I measured the milling spindle nut and defined this as the inner diameter.

The Calculation

The diameter of the vacuum cleaner handpiece gives me the ideal flow area.

The extraction system on the milling machine will now be a pipe with an inner area that is not exposed to airflow. So I now need the outer diameter.

So for the extraction system, we have an area of the spindle that is not exposed to airflow, and we now determine the outer diameter, which extends the spindle area by the diameter of the handpiece.

Now we have an extraction system that should not strain the vacuum cleaner and can therefore be used for a very long time without the vacuum cleaner overheating.

Attention, you still need to pay attention to the distance between the end of the extraction port and the workpiece, because if the distance is too small, especially with panels, the vacuum cleaner can be overloaded!

Design

Now that the diameter is defined, the question arises: what should the whole thing look like, how can I attach the extraction port to the milling head, and how do I access the spindle to change the cutter? Of course, I didn't want to make it easy for myself and also asked myself how I can adjust the height of the extraction port.

1. Securing the vacuum cleaner handpiece to the milling head

The manufacturer already offers dust extraction systems like the one I designed for woodworking, and these are available

First Use

Success! The dust extraction system works better than expected and really sucks up everything that is produced

Update:

After a few uses, having significantly optimized the milling parameters and now producing considerably more and larger chips, a few larger chips occasionally end up outside the extraction area, but I am still extremely satisfied, as only very small chips escape

Conclusion

Dust extraction makes sense for aluminum, wood, and fiber composite panels, and additional cooling is not necessary. Most of the dust is extracted, leaving only minimal chips, but significantly more material is removed than I expected, and the aluminum is cooled better than anticipated. For perfect surfaces, a very thin layer of viscous lubricant can be applied with a brush before the finishing pass. This upgrade is a no-brainer for me; anyone with a small milling machine should install it.

Verwendetes Equipment

Fusion 360 - Autodesk

Autodesk Fusion 360 ist eine cloudbasierte Komplettlösung für 3D-CAD, CAM, CAE und Leiterplatten, die Konstruktion, Simulation und Fertigung in einer Plattform vereint.

Genmitsu Sainsmart 3030-PROVer MAX

Nach langem Suchen nach einer preiswerten, kleinen, aber dennoch leistungsfähigen Fräse stieß ich schlussendlich auf die Genmitsu 3030-PROVer Max eine 30x30cm CNC-Fräse mit Kugekunlaufspindeln und Linearführungen und guter Implementation, damit man damit auch Alu fräsen kann.

SJT S1 mein erster Modularer 3D Drucker

Da ich beruflich schon über 5 Jahre mit 3D Druck zu tun hatte und privat auch schon mehrere Jahre einen günstigen China 3D Drucker hatte, aber einfach nicht mit der Leistung zufrieden war, aber auch keinen Drucker kaufen konnte, der all meine Anforderungen auf der Wunschliste abhakte, begann ich meinen eigenen zu entwickeln.

Updates

| 2025-08-28 |